When grinding and polishing quartz, choosing the right sandpaper is essential to achieving the desired finish and ensuring the longevity of the material. Quartz, known for its durability and beauty, requires specific abrasives to enhance its natural beauty while maintaining its structural integrity. Here are some tips for selecting and using sandpaper for quartz.

Material Properties and Sandpaper Matching Principles

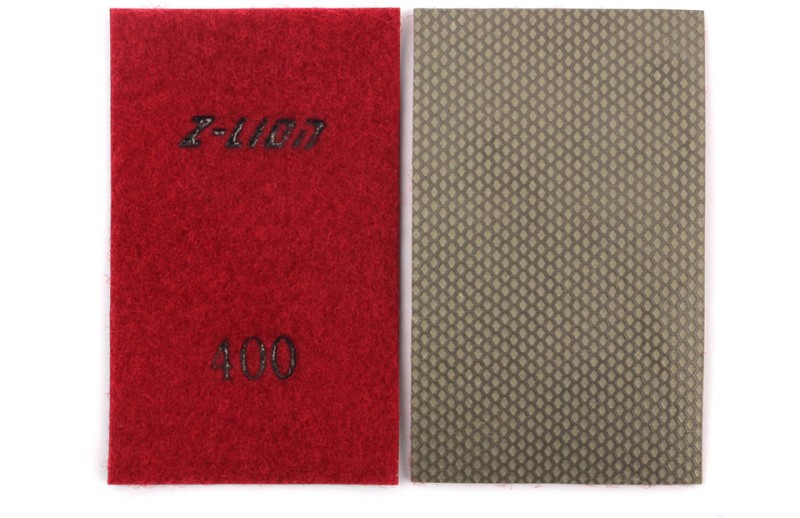

1. Diamond sandpaper

Features: Diamond sandpaper is made of super-hard diamond abrasives and is the best choice for precision polishing and gloss enhancement. The hardness of diamond enables it to efficiently remove material and achieve high-quality surface treatment.

Best uses:

Precision polishing: Ideal for achieving a high gloss finish on quartz surfaces, especially in the final stages of processing.

High precision processing: For complex designs and detail work where precision is critical.

Usage tips:

Use diamond sandpaper systematically, starting with coarser grit and gradually moving to finer grit to achieve the desired smoothness and gloss.

Keep the surface wet while polishing to reduce heat and prevent damage to the quartz.

2. Silicon carbide sandpaper

Features: The abrasive particles of silicon carbide sandpaper are evenly distributed and have strong wear resistance. This sandpaper is suitable for grinding and shaping quartz stone.

Best uses:

Flatness correction: Ideal for correcting uneven surfaces and ensuring a flat surface.

Transition grinding: Suitable for mid-term grinding, where a balance between material removal and surface smoothness is required.

Usage tips:

Start with a coarser grit to quickly remove material, then transition to a finer grit for a smoother surface.

Use water or lubricant to reduce dust and improve the grinding process.

3. Aluminum oxide sandpaper

Features: Aluminum oxide sandpaper is a more economical choice, and its durable abrasive grain is ideal for light sanding. However, it is not ideal for heavy sanding.

Best uses:

Cleaning light stains: Great for removing light stains or blemishes from your quartz surface.

Light trimming: Suitable for fine-tuning and pre-treatment tasks before more intensive grinding.

Usage tips:

Use aluminum oxide sandpaper with caution as it is not designed for removing heavy materials.

Make sure the surface is clean before using sandpaper to avoid scratching the quartz.

General tips for using sandpaper

Sandpaper selection: Always use coarser sandpaper to remove material first, then gradually use finer sandpaper for polishing. The grit number of sandpaper indicates the size of the abrasive particles; the lower the grit number, the coarser the abrasive; the higher the grit number, the finer the abrasive.

Test on a small area: Before applying any sandpaper to an entire surface, test it on a small, inconspicuous area to ensure compatibility and intended results.

Maintain consistent pressure: Apply even pressure when sanding to avoid surface unevenness and ensure an even finish.

Keep the surface moist: For most types of quartz grinding, keeping the surface moist helps reduce dust, prevents overheating, and improves the overall result.

Safety precautions: Always wear appropriate personal protective equipment such as gloves and masks to protect against dust and debris.

Particle Size Classification and Grinding Process Control

Granularity classification

1. Coarse grain (800-1000 mesh)

Features: Coarse-grain sandpaper is suitable for deep scratches and severe surface unevenness. Larger abrasive particles can effectively remove surface material.

Best uses:

Deep scratch removal: Great for addressing severe imperfections on quartz surfaces.

Correct bumpy surface: Helps to level out uneven areas.

Grinding process control:

Time management: When using coarse sandpaper, be sure to carefully control the grinding time to prevent excessive wear on the quartz surface. Over-grinding may cause unnecessary damage and may require additional finishing work.

2. Medium grain (1200-1500 mesh)

Features: Medium-grit sandpaper is the workhorse of traditional sanding, striking a balance between efficiency and sanding effect.

Best uses:

General grinding: Effective for smoothing the surface after initial rough grinding.

Balanced efficiency and fineness: Suitable for most grinding tasks that require a good surface finish without investing too much time.

Grinding process control:

Transition: After using the coarse sandpaper, switch to the medium sandpaper and further sand the surface. This stage is essential to prepare the surface for the finer sandpaper.

3. Fine particles (2000 mesh and above)

Features: Fine sandpaper is designed for the final polishing stage. The extremely fine abrasive particles give a high-gloss surface effect.

Best uses:

Final polish: Ideal for achieving a mirror-like effect on quartz surfaces.

Grinding process control:

Time limit: Each operation with fine sandpaper should not exceed 5 minutes. Prolonged use may cause overheating and may damage the surface.

Notes on scene operation

1. New quartz

Recommended process: For new quartz surfaces, a three-stage grinding process is recommended:

Stage 1: Start by using medium grit sandpaper (1200-1500 grit) to create a smooth base.

Stage 2: Transition to fine sandpaper (2000 grit and above) for initial polishing.

Stage 3: Sand with additional fine sandpaper to achieve desired glossiness.

Important: Avoid using sandpaper lower than 800 grit at first as this will cause excessive scratching and damage.

2. Refurbished quartz

Recommended procedure: If there is structural damage to the quartz surface, follow these steps:

Basic treatment: Start by using 800 grit sandpaper to treat deep scratches and blemishes.

Standard process: After basic treatment, a standard three-stage grinding process is carried out to refine and polish the surface.

3. Special texture quartz

Recommended process: For quartz with unique textures or patterns, it is critical to adjust the grinding technique:

Dynamic adjustment: Grinding angle and pressure are continuously adjusted according to the distribution density of the quartz particles. This ensures that the grinding process is effective without compromising the integrity of the material.

In Conclusion

Choosing the right sandpaper for quartz grinding is essential to achieving a high-quality polish and maintaining the integrity of the material. Understanding the properties and best uses of diamond, silicon carbide, and aluminum oxide sandpapers will help you make an informed decision for successful grinding and polishing results. Be sure to follow best practices and safety practices to ensure a smooth and efficient process.

Post time: Jun-20-2025