Sanding is a special textile finishing process that mechanically abrades the surface of the fabric to give it a fine, soft texture. This process is particularly suitable for producing soft and luxurious fabrics in clothing, interior decoration and other textile applications. The use of diamond belts in the sanding process has revolutionized the textile industry and has many advantages over traditional methods.

Peaching Process

1. Fabric preparation

The first step in the sanding process is to prepare the base fabric, which can be made of cotton, polyester or a blend. Proper preparation is essential to ensure uniform sanding and the best results. The base fabric undergoes several pre-treatment steps, including:

Desizing: Removal of sizing agents that may interfere with the abrasion process.

Scrub: Cleans fabric to remove impurities and enhance absorbency.

Bleach: To lighten fabric to achieve an even color and improve appearance.

These treatments ensure that the fabric is ready for the sanding process, resulting in consistent results.

2. Sanding belt selection

Selecting the right belt is essential to achieving the desired texture. Diamond-coated belts, typically around 220 grit, are favored for their durability and ability to provide a consistent finish. Diamond abrasives are embedded in the belt material, allowing for effective grinding without excessive wear.

3. Machine settings

Once the fabric is prepared and the appropriate abrasive belt is selected, the next step is to set up the sander. The fabric is fed into the sander, which is equipped with a rotating diamond belt. Key factors to consider during the setup process include:

Controlled tension: Make sure the fabric passes through the machine under controlled tension to prevent deformation.

Speed adjustment: Set the machine speed to optimize the wearing process while maintaining fabric integrity.

4. Surface wear

During the sanding process, diamond grit on the belt gently abrades the fabric surface. This action fluffs the microfibers without damaging the underlying fabric, resulting in a soft, velvety texture. The precision of the diamond abrasive allows it to grind evenly, which is essential to achieving a consistent finish across the entire fabric surface.

5. Final check

After the sanding process is completed, the treated fabric is thoroughly inspected. The quality control inspection focuses on the following factors:

Uniformity: Ensures consistent texture across the entire fabric.

Softness: Assess the tactile qualities of the fabric to confirm it meets softness standards.

Free from defects: Any defects or irregularities that may have appeared during the inspection.

Final inspection is essential to maintain high quality standards of the finished product.

Why Diamond Belts Work Well in Peaching Processing

Using diamond belts in the grinding process has several advantages over traditional abrasives:

Longer service life

Diamond abrasives are known for their superior durability, lasting 50-70% longer than conventional belts. Longer life reduces the frequency of belt changes, which reduces operating costs and downtime.

Consistent completion

The even distribution of grit on diamond abrasive belts prevents streaking and ensures an even fabric texture. This consistency is essential to producing the high-quality textiles that consumers expect.

Heat resistance

Diamond’s excellent thermal conductivity minimizes the risk of scorching, which is particularly important when processing delicate synthetic fibers. This property ensures safer processing without compromising the integrity of the material.

Environmental friendly

Reducing the number of belt changes reduces waste and energy consumption, making the use of diamond belts a more environmentally friendly choice. This is in line with the growing demand for sustainable practices in the textile industry.

Case Study: Improving Efficiency in a Textile Factory

A textile manufacturer in China recently replaced traditional silicon carbide belts on its grinding machines with 220-grit diamond belts. The results were dramatic:

50% Fewer belt changes: The durability of the diamond belts has resulted in significantly less frequent replacements, saving the company around €12,000 per year.

30% lower energy consumption: The reduction in diamond belt friction results in lower energy consumption during the grinding process, improving overall operational efficiency.

Zero fabric burning: Diamond’s thermal conductivity minimizes the risk of burning delicate fabrics, thereby improving product quality and customer satisfaction.

These efficiency gains not only improve manufacturers’ profitability but also position them as leaders in sustainable textile production.

Technical Specifications for Peaching Applications

To achieve optimal performance in grinding applications, the following technical specifications of diamond belts should be considered:

Grit: 220 (suitable for fine, soft surfaces)

Width: 75 mm (standard for industrial machines)

Length: 6600 mm (ensures seamless handling of large rolls)

Quantity: 24 rolls (mass production is cost-effective)

These specifications ensure that diamond abrasive belts perform effectively in high-volume textile operations, providing consistent results and reducing downtime.

The Future Trend of Grinding Technology

1. Automation and intelligent control

One of the most important trends in peach peel grinding technology is the increasing popularity of automation and intelligent control. Modern peach peel grinders are equipped with programmable logic controllers (PLCs) that allow real-time adjustments during the grinding process. The main benefits of this trend include:

Improved consistency: Automated systems can monitor and adjust parameters such as tension and speed in real time to ensure that the fabric passes through the rollers in optimal conditions. This can make the finished product more uniform and reduce the risk of defects.

Increased efficiency: Automation minimizes human error and increases production speed, allowing manufacturers to meet growing demand without compromising quality.

Data-driven insights: Intelligent controls can collect data from the peach picking process, providing valuable insights that can be used to optimize operations and improve overall performance.

2. Environmentally friendly abrasive

As sustainability becomes a priority for the textile industry, the demand for environmentally friendly abrasives is growing. Sustainable diamond-coated abrasive belts are becoming a viable alternative to traditional abrasives. The benefits of environmentally friendly abrasives include:

Reduce environmental impact: Sustainable diamond abrasive belts are designed to minimize waste and energy consumption, in line with green manufacturing practices. Their longer life means fewer replacements, resulting in less material waste.

Non-toxic materials: Many environmentally friendly abrasives are made from non-toxic materials, ensuring a safer working environment for operators and reducing harmful emissions during production.

Consumer demand: As consumers become more environmentally conscious, manufacturers that adopt eco-friendly practices can enhance their brand image and appeal to a wider audience.

3. Custom grit solutions

Another emerging trend in polishing technology is the development of customized grit solutions. While traditional diamond abrasive belts are typically available in 220-grit grit, there is a growing demand for finer grits (e.g., 400-grit and above) to achieve premium fabric finishes. The benefits of customized grit solutions include:

Enhanced texture: Finer grit allows for a finer finish, giving high-end fabrics a softer, more luxurious feel. This is especially important in a market where touch is a key selling point.

Versatility: Custom grit solutions enable manufacturers to tailor their sanding process to specific fabric types and desired finishes, providing greater flexibility in production.

Market differentiation: By offering unique fabric finishes, manufacturers can differentiate their products in a competitive market and attract discerning customers seeking high quality.

Industry Case Studies

Understanding the peaching process

Sanding is a finishing process used in denim production to give the fabric a soft, silky feel. Traditionally, the process required the use of abrasive materials that wear quickly, resulting in a high rate of rejects. However, the advent of diamond abrasive belts revolutionized the process, increasing durability, reducing energy costs, and improving fabric quality.

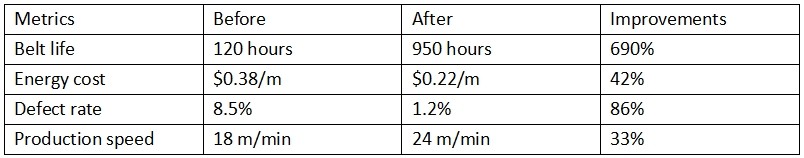

Significant effect: before and after comparison

The application of diamond abrasive belts has significantly improved the denim manufacturer’s operations. The following indicators reflect the huge impact of this technology:

Major improvements

1. Belt life: The service life of diamond belts significantly exceeds that of conventional belts, extending from 120 hours to an impressive 950 hours. This extension not only reduces the frequency of replacement, but also minimizes downtime and maintenance costs.

2. Energy cost: Energy cost per meter was reduced by 42%, from $0.38 to $0.22. This reduction is due to the efficient cutting of the diamond belt, which can achieve the required surface finish with lower energy.

3. Defect rate: The defect rate dropped significantly from 8.5% to 1.2%, demonstrating the excellent processing quality brought by diamond belts. This improvement increased customer satisfaction and reduced waste.

4. Production speed: The production speed has increased by 33%, from 18m/min to 24m/min. The increase in efficiency enables manufacturers to meet the growing demand without compromising quality.

Implementation guide

To achieve similar results, manufacturers should follow the following implementation guidelines:

1. Machine compatibility check

Before installing a diamond belt, always make sure your existing equipment is compatible. Key checks include:

Roller hardness: Verify that the roller hardness is at least 80 Shore D to withstand the abrasiveness of the diamond belt.

Dust removal capacity: Confirm that the dust removal system can handle at least 30 cubic meters of dust per minute to maintain a clean working environment.

Drive system torque requirements: Evaluate the drive system torque requirements to ensure it can support the new belt.

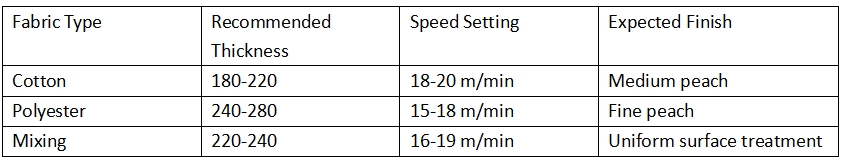

2. Belt Selection Matrix

Selecting the right diamond abrasive belt is essential to achieving optimal performance. The following table provides guidance based on fabric type:

3. Maintenance Agreement

Regular maintenance is essential to ensure the life and performance of your diamond belt. It is recommended to follow the following regimen:

Daily: Visually inspect belts and rollers for debris buildup.

Weekly: Verify belt tension using digital meter to ensure optimal performance.

Monthly: Perform a complete system calibration to maintain accuracy and efficiency.

Conclusion

The integration of diamond emery belts in peaching operations represents a quantum leap in textile finishing technology. By delivering superior quality, unprecedented efficiency, and remarkable cost savings, this innovation is setting new industry standards. Forward-thinking manufacturers are adopting diamond abrasives not just as equipment upgrades, but as strategic investments in competitive advantage.

Post time: Jun-13-2025