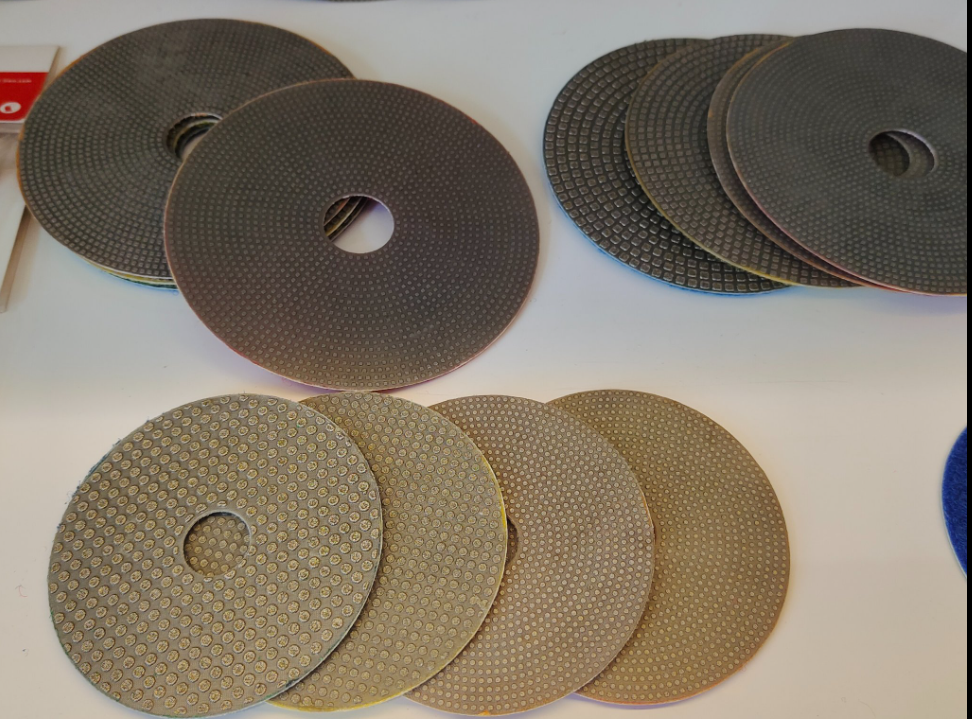

Diamond polishing pads is a popular polishing and grinding tool at present. It can be used to process materials such as stone, ceramics, floor tiles and glass. It is an ideal grinding tool. What are the specifications of diamond polishing pads? This is a question that many people want to know. Next, Z-LION will introduce the specifications and usage requirements of diamond polishing pads.

Specifications of diamond polishing pads

The specifications of diamond polishing pads are usually 4 inches about 100mm, and there are many thicknesses, such as 3mm, 4mm, 6mm, 8mm, 10mm and so on. There are also many kinds of meshes, specifically 30#, 50#, 100#, 150#, 200#, 300#, 400#, 500#, 600#, 800#, 1000#, 1500#, 2000#, 3000#, etc. , which specification of diamond polishing sheet should be selected depends on the processing material and actual use.

Features of diamond polishing pads

1. The special resin bond is selected, so the softness of the diamond polishing sheet is very good, which is convenient for subsequent installation and use.

2. The grinding force of the diamond polishing pad is very strong. Using it to polish the material will be faster than other polishing pads, and the gloss will be better.

3. Good wear resistance and long service life.

4. After polishing and grinding the floor with a diamond flexible polishing pads, there will be basically no scratches or staining.

Requirements for the use of diamond polishing pads

1. Before starting work, confirm whether the polishing sheet and the workpiece are fixed, and whether the positioning of the profile conforms to the direction of the knife, so as to avoid abnormal cutting.

2. When using the polishing pad, do not apply pressure from the side or use the curved cutting method. The feed should be stable to avoid the impact of the blade contacting the workpiece, which may cause the polishing pad to be damaged or the workpiece to fly out, resulting in an accident.

3. When working, if you find noise, abnormal vibration, rough cutting surface or peculiar smell, you need to stop the operation immediately, and then check and confirm, and troubleshoot to avoid accidents.

4. When starting and stopping cutting, do not feed too fast to avoid broken teeth or damage.

5. The equipment chip removal groove and slag suction device ensure smooth flow to prevent the slag from accumulating and affecting production and safety.

6. When dry cutting, please do not continuously cut for a long time, so as not to affect the service life and cutting effect of the diamond polishing sheet; for wet cutting, water should be added to cut to prevent leakage.

7. If cutting aluminum alloy or other metals, special cooling lubricant should be used to prevent tooth paste or other damage due to overheating of the grinding disc, which will affect the overall cutting quality.

The above is z-lion introduction to the specifications, characteristics and usage requirements of diamond polishing pads. Through the above, we can have a clear understanding of diamond polishing pads. If you want to know more about diamond polishing pads, please contact Xiamen ZL Diamond Technology Co., Ltd., we will answer your doubts in time.

Post time: Jul-07-2022