When grinding concrete floors, choosing the right abrasive disc is crucial to achieving the desired results. The choice of disc significantly impacts the efficiency, quality, and finish of the concrete surface. The two most common types of abrasive discs are diamond discs and resin discs. Each has unique properties and uses, suited for different tasks. This article will explore these two types of discs and their specific uses in concrete floor grinding.

Diamond Grinding Wheel

Overview:

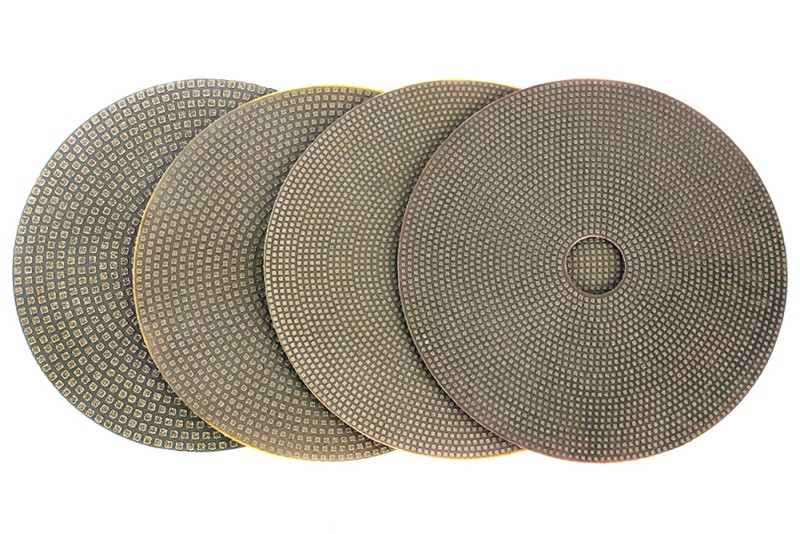

Diamond grinding discs are widely considered the tool of choice for grinding concrete floors. They are made from synthetic or natural diamond powder, which provides exceptional hardness and durability.

Main features:

High hardness: The hardness of diamond enables these discs to effectively grind hard concrete surfaces, making them ideal for heavy-duty applications.

Wear resistance: Diamond grinding discs have strong wear resistance and have a longer service life compared to other types of grinding discs.

Thermal stability: These discs can withstand the high temperatures generated during the grinding process, maintaining their performance without degradation.

Application:

Surface preparation: Diamond abrasive discs are ideal for removing films, coatings, and surface imperfections from concrete floors.

Smoothing and polishing: Depending on the particle size and shape, they can achieve a variety of surface finishes, from aggressive grinding to fine polishing.

Wet or dry grinding: Diamond discs can be used for both wet and dry grinding, allowing flexibility based on the specific requirements of your project.

Choose the right diamond grinding disc:

Grit size: Choose finer grit for polishing and coarser grit for aggressive grinding and material removal.

Bond type: The bond type (soft, medium, hard) should be selected based on the hardness of the concrete. Soft bond is suitable for harder concrete, while hard bond is suitable for softer concrete.

Resin Grinding Disc

Overview:

Resin grinding wheels, also known as resin grinding wheels, are made of a mix of resin, abrasives, and fillers. They are designed for specific applications that require a finer touch.

Main features:

Elasticity and flexibility: Resin grinding wheels utilize a special bonding process that gives them excellent elasticity, allowing them to perfectly conform to the surface being ground. This property helps control surface defects and minimize damage.

Lower hardness: Resin discs are softer than diamond discs and are suitable for fine grinding and finishing tasks.

Application:

Smooth and fine grinding: Resin grinding discs are ideal for achieving a smooth finish on concrete surfaces after initial grinding with diamond grinding discs.

Surface treatment: They are particularly effective for improving the overall appearance of concrete, making it suitable for decorative concrete applications.

Choose the right resin grinding disc:

Grit size: Similar to diamond grinding wheels, grit size should be selected based on the desired finish. Fine grit is used for polishing, and coarse grit is used for initial sanding.

Application Type: Consider specific application requirements, such as whether the surface is already ground or if more aggressive material removal is required.

Selection Suggestions

When choosing a grinding disc for concrete floors, consider the following:

Ideal results: If your goal is to smooth the concrete surface and achieve a high-quality polish, we recommend using a diamond grinding disc. Its higher hardness provides an excellent polishing effect and effectively removes surface defects.

Surface smoothness and flatness: If you need to improve surface smoothness and flatness without excessive material removal, resin grinding wheels are a better choice. Their relatively soft texture allows for controlled grinding depth, effectively reducing surface blemishes and damage.

Application requirements: Consider whether you will be performing dry or wet sanding. Diamond discs can be used for both applications, while resin discs are generally more effective in wet conditions, reducing dust and improving surface finish.

In Conclusion

Ultimately, choosing a grinding disc for concrete floors should be based on the specific requirements of your project. Diamond grinding discs are ideal for heavy-duty grinding and polishing, while resin grinding discs excel at fine grinding and surface finishing. Understanding the characteristics and applications of each type of grinding disc will help you make an informed decision and achieve the best results in your concrete grinding project. Whether you’re preparing a surface for coating or applying a polishing finish, choosing the right grinding disc is crucial to success.

Post time: Sep-30-2025