-

Polishing is a crucial process in ceramic production, significantly impacting all aspects of the final product. From improving surface finish to enhancing dimensional accuracy, polishing plays a vital role in ensuring ceramic materials meet the stringent requirements of modern applications. Poli...Read more »

-

Marble is a luxurious and elegant material that can enhance the aesthetic value of any space. However, over time, daily use, high traffic, or improper maintenance can cause scratches and imperfections on the marble surface, affecting its beauty. Fortunately, there are many effective methods to so...Read more »

-

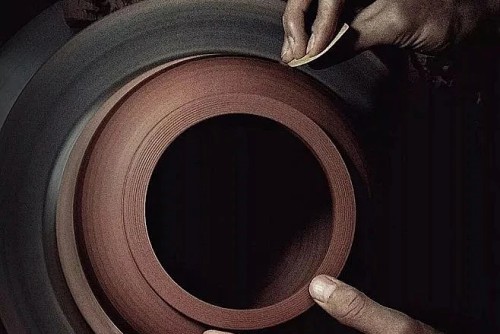

Grinding and polishing ceramics is a delicate process that enhances both the aesthetics and functionality of ceramic surfaces. Whether you’re working with tiles, pottery, or other ceramic products, following the correct steps is crucial for achieving a smooth, glossy finish. This article outlines...Read more »

-

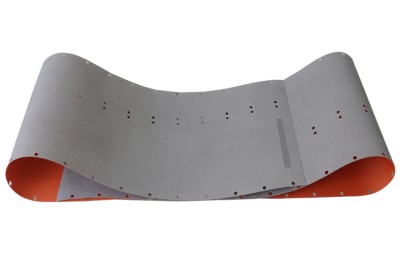

In the fast-paced and highly competitive textile manufacturing industry, precision and efficiency are paramount. Manufacturers constantly strive to improve production processes and enhance the quality of their final products, making the adoption of advanced tools and technologies essential. Diamo...Read more »

-

Using an angle grinder to sand concrete is an effective way to obtain a smooth, flat surface or remove imperfections. However, to ensure safety and effectiveness, proper operating procedures and preparation must be followed. This article outlines the necessary steps for correctly sanding concrete...Read more »

-

Sandpaper is an essential tool in various industries, from woodworking and metalworking to glass and stone polishing. Choosing the right sandpaper can significantly impact work quality and polishing efficiency. This guide will introduce different types of sandpaper substrates, abrasive types, and...Read more »

-

Electroplated diamond grinding discs are advanced abrasive tools that utilize the exceptional hardness and cutting power of diamond particles. These wheels are designed for high-performance abrasive applications across a variety of industries, including stone processing, metal cutting, and precis...Read more »

-

For diamond grinding discs, the choice between dry and wet grinding is crucial, directly impacting machining results in various applications. Each method has its own advantages and disadvantages, significantly affecting the grinding process, surface quality, and overall efficiency. This article w...Read more »

-

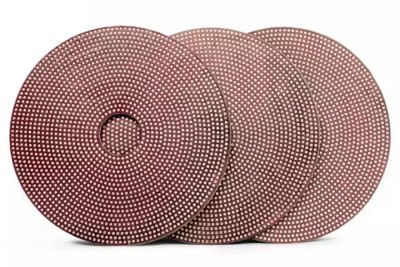

What Are Diamond Grinding Discs? Structure of a diamond grinding disc Diamond grinding discs are composed of three main materials, each of which plays a specific role: Basal layer: The base layer is typically made of a robust material such as steel or aluminum alloy. This layer provides the nec...Read more »

-

Diamond grinding pads, also known as diamond polishing pads, are a crucial component of bonded abrasive grinding technology. These pads are made by chelating diamond micropowder with resin, resulting in high hardness, excellent wear resistance, and superior efficiency. Their unique properties mak...Read more »

-

The textile manufacturing industry is a complex ecosystem that heavily relies on high-precision machinery to ensure consistent product quality and maximize production efficiency. In this environment, effective maintenance is crucial to prevent downtime and maintain the integrity of the production...Read more »

-

Diamond flap discs represent a major innovation in the field of abrasive tools, designed for the efficient and precise machining of hard materials. Unlike traditional abrasive wheels made of abrasives such as silicon carbide or zirconium oxide, diamond flap discs utilize the unparalleled hardness...Read more »