Diamond polishing pad is the general name of diamond wet polishing pads and dry polishing pads. Diamond wet polishing pads is also called diamond soft grinding pads. On the joint of the grinding machine, it is used for grinding, and can be used for special-shaped processing of stone, ceramics, glass, floor tiles and other materials. It is suitable for stone polishing, line chamfering, curved plate and special-shaped stone processing. It can also be used for marble, mixed Special-shaped processing, repair and renovation of concrete, cement floor, terrazzo, glass-ceramic, artificial stone, floor tile, glazed tile and vitrified tile, with strong grinding force, good durability, good softness, clarity and gloss , is an ideal stone grinding tool. The whole process is divided into four stages: rough grinding, fine grinding, fine grinding and polishing. The processed stone has a glossiness of more than 90°.

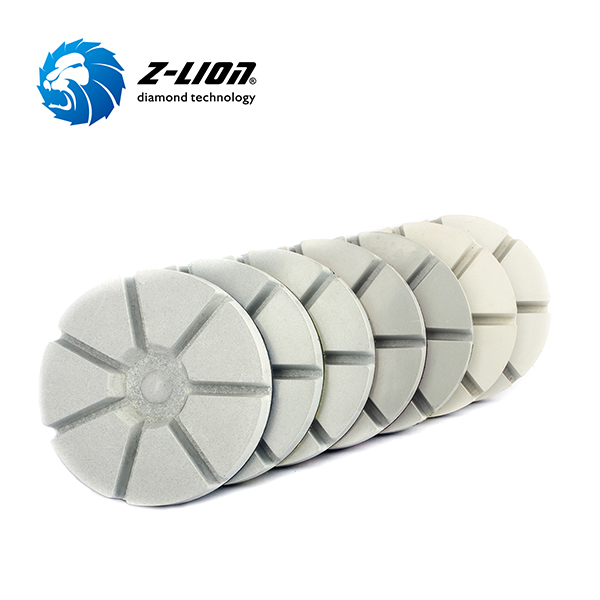

Application of diamond dry polishing pads:

1. It is used for the processing of artificial stone, granite and marble, etc. It has a complete and standardized particle size color system and good flexibility. It is handy in processing lines, chamfers, curved plates and special-shaped stones, and there are various shapes and specifications to choose from. , Various particle size numbers are easy to identify, and can be used flexibly with various hand mills according to needs and habits.

2. It is used for the treatment and renovation of various floors and steps after granite, marble and artificial stone slabs are laid. It can be used flexibly with various hand grinders or renovation machines according to needs and habits.

3. For the grinding and polishing of ceramic tiles, the ceramic tile manufacturers are equipped with manual and automatic full polishing machines and half polishing machines for full polishing and half polishing treatment of microcrystalline tiles, glazed tiles and antique tiles. The brightness value of the glossy surface can reach more than 90; it is used for ground treatment and renovation of microcrystalline bricks and various ceramic tiles, and can be flexibly used with various hand grinders or renovation machines according to needs and habits.

4. It is used for the renovation of industrial floors, warehouses, parking lots and other concrete floors or various aggregate hardener floors, especially for today’s popular liquid hardener floor projects. It can be flexibly matched with various hand grinders according to needs and habits. For machine or refurbished machine use, choose DS grinding discs of different particle sizes for rough grinding, fine grinding and polishing.

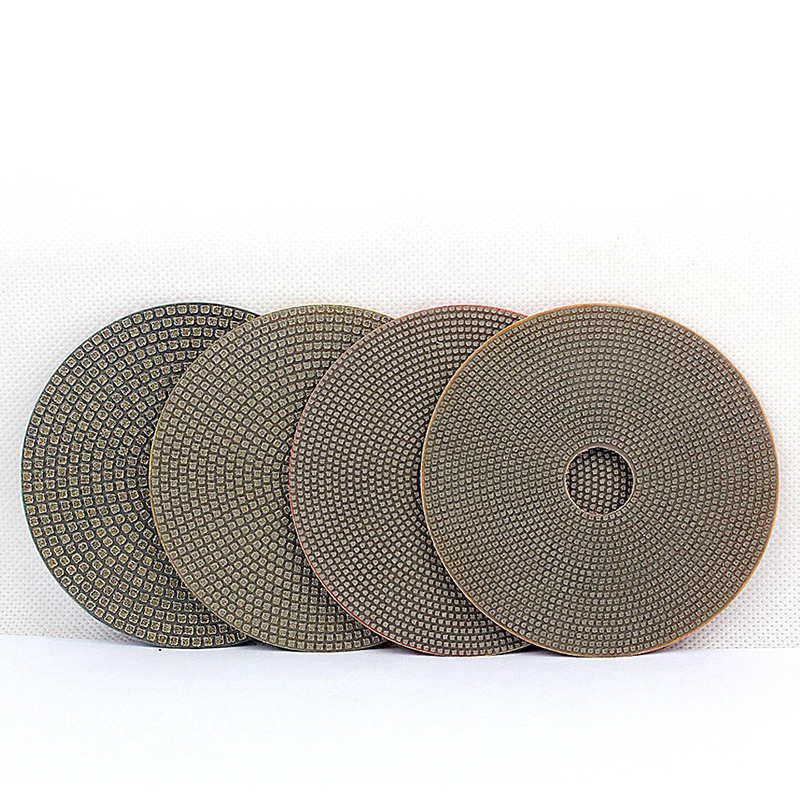

Diamond wet polishing play a very important role in the process of our stone renovation. Generally, the diamond grinding discs and diamond soft (water) grinding discs we use use high-quality diamond powder and resin bond materials, with exquisite technology and advanced technology. It is produced by the production process. The grinding disc is fast, sharp, stable in quality, long in service life, high in work efficiency, fast in surface polishing, environmentally friendly, non-toxic and non-fading. It is now widely used in stone processing, floor renovation, and ceramic tile production. and other industries.

Soft (water) grinding discs have uniform grain size and color and good flexibility. They are widely used in the processing of lines, chamfers, countertops, curved plates and special-shaped stones such as granite, marble, artificial stone, etc. The shapes and specifications are optional, and various particle sizes are distinguished by different colors, which can be flexibly matched with various hand grinders, floor stone refurbishment machines, and ceramic polishing machines according to the needs and habits of customers. The diamond soft (water) grinding disc can efficiently complete the polishing and grinding of stone, glass, ceramics and other materials under the condition of adding water. Spiral soft (water) grinding disc has the advantages of sharp grinding, good heat resistance and pressure resistance, and without changing the color of the stone itself, it has the advantages of fast glazing, high brightness and not easy to fade, and has won the majority of users. Approved!

Post time: Jun-01-2022