Ceramic products are highly sought after for their unique texture, durability, and aesthetic appeal. However, over time, ceramic surfaces may develop scratches, dullness, or stains, affecting their appearance and overall look. To address these issues, ceramic polishing pads have emerged as essential tools for restoring and enhancing the gloss of ceramic surfaces.

Functions of Ceramic Polishing Pads

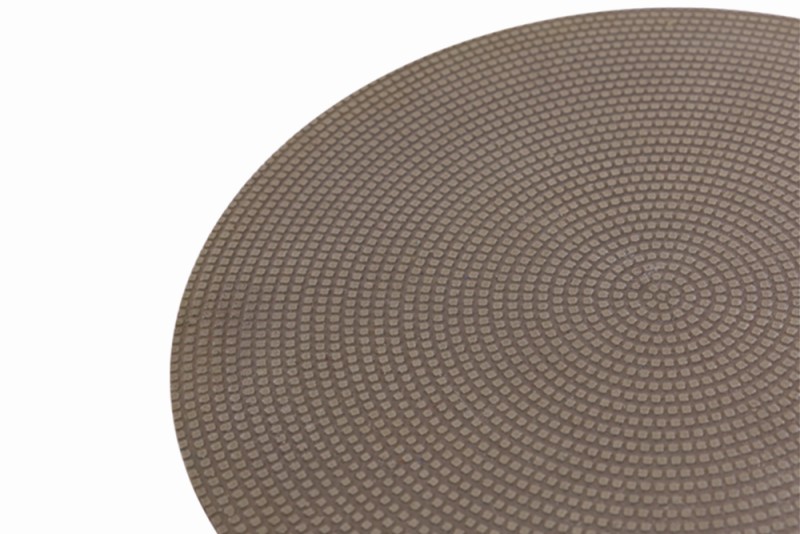

Ceramic polishing pads are specialized tools designed to enhance the gloss of ceramic surfaces. They consist of a combination of abrasive materials and advanced binders, enabling effective polishing and refining of ceramic surfaces. The main functions of ceramic polishing pads include:

Enhancing surface gloss: The primary purpose of ceramic polishing pads is to form a smooth, glossy film on the ceramic surface. This process not only improves the aesthetics of the ceramic but also provides a protective layer that helps resist future wear and tear.

Removal of scratches and stains: Ceramic polishing pads effectively remove minor scratches, stains, and imperfections from ceramic surfaces. Using the right polishing pad and techniques, users can restore the original shine to ceramic products, making them look brand new.

Smoothing uneven surfaces: Besides enhancing gloss, polishing pads can also help smooth out uneven areas on ceramic surfaces. This is especially important for tiles and countertops, as a smooth surface is crucial for both aesthetics and functionality.

Application of Ceramic Polishing Pads

Ceramic polishing pads are versatile tools used in a wide range of applications, including home décor, art restoration, and industrial applications. Below are some common applications of ceramic polishing pads:

Home decor: In residential environments, ceramic polishing pads are widely used to polish ceramic products such as tiles, washbasins, bathtubs, and decorative items. By using polishing pads, homeowners can enhance the overall quality of their living space, making it more visually appealing and inviting.

Art restoration: Ceramic polishing pads play a vital role in the restoration of ancient ceramic artifacts. Restorers use these pads to repair surface damage, remove dirt and oil stains, and restore the original luster of historical relics. This meticulous restoration process helps protect cultural heritage and allows future generations to appreciate the beauty of these artifacts.

Industrial applications: In industrial environments, ceramic polishing pads are used to finish ceramic components during the manufacturing process. They help achieve the desired surface finish on products such as ceramic tiles, sanitary ware, and technical ceramics, ensuring they meet quality standards and customer expectations.

Automotive and aerospace industries: Ceramic polishing pads are also used in the automotive and aerospace industries for polishing ceramic coatings and components. These pads help achieve high-gloss surface finishes on parts that require both aesthetics and functionality.

How to Choose the Right Ceramic Polishing Pad?

Choosing the right ceramic polishing pad is crucial for achieving the desired polishing results without damaging the surface. Here are the key factors to consider when making your selection:

Materials:

The material of a polishing pad plays a crucial role in its effectiveness and safety. A high-quality polishing pad should be made of a soft, durable material that effectively polishes ceramic surfaces without causing scratches or damage. Please choose polishing pads made of materials such as foam or specialty synthetic fibers designed specifically for ceramic applications.

Particle size:

The grit size of the polishing pad directly affects the polishing effect. Grit sizes are generally classified into three types: coarse, medium, and fine.

Coarse grit: Ideal for removing deeper scratches and blemishes, but may leave a rougher surface.

Medium grit: This offers both scratch removal and surface smoothing, making it a versatile option.

Fine sandpaper: Best suited for achieving a high-gloss finish, but may require more time to polish effectively.

Finding the right sandpaper grit for your specific needs is crucial. For example, if you’re working on a heavily scratched surface, it’s best to start with coarse sandpaper and gradually switch to finer grit for optimal results.

Brand reputation:

When choosing polishing pads, brand reputation is paramount. Reputable, well-known brands typically offer higher quality products and more comprehensive after-sales service. Check customer reviews and seek recommendations to ensure you purchase a reliable product. Choosing a reputable brand also gives you greater peace of mind regarding the durability and effectiveness of the polishing pads.

Application method:

Consider how you intend to use the polishing pad. Some polishing pads are designed for polishing machines, while others can be used manually. For best results, ensure that the polishing pad you choose is compatible with your preferred method of use.

Thickness and flexibility:

The thickness and flexibility of a polishing pad also affect its performance. Thicker polishing pads provide better cushioning, which is beneficial for handling uneven surfaces; while thinner polishing pads allow for more precise control. The appropriate thickness should be chosen to meet your specific polishing needs.

In Conclusion

Ceramic polishing pads are truly “magic weapons” for enhancing the shine of ceramic products, giving them a renewed vitality and beauty. By carefully considering factors such as material, grit size, brand reputation, usage method, and thickness, you can choose the right polishing pad for your needs. With the right tool, you can effectively restore the luster of your ceramic products, ensuring they remain a beautiful addition to your home or workplace. Whether you’re polishing tiles, washbasins, or artistic ceramic ornaments, the right polishing pad will help you achieve a flawless finish.

Post time: Oct-31-2025