Mirror polishing of marble surfaces requires meticulous attention to detail and the use of high-precision grit sandpaper to achieve a smooth, shiny finish. Choosing a specific grit sandpaper plays a vital role in refining the marble surface and creating a mirrored effect. In this article, we’ll explore the importance of using diamond sandpaper to mirror polish marble and the specific considerations for achieving the ideal result.

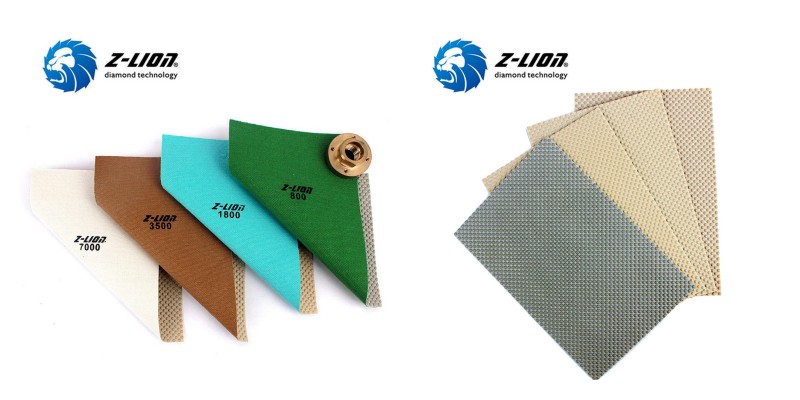

Generally, when mirror-polishing the marble surface, you need to use sandpaper between 800 and 3000 grit for multiple polishing and polishing to achieve the desired effect.

Selection of Grit

Repeated grinding and polishing with sandpaper between 800 and 3000 grit is crucial to achieving the ideal mirror effect on the marble surface. The high precision and fine grit of these sandpapers help refine the surface and create a smooth and shiny surface, ultimately achieving a mirror finish.

Basic Tips for Polishing Marble Surfaces

Polishing a marble surface is a meticulous process that requires precision, skill, and adherence to basic guidelines to achieve the best results. From cleaning the surface to using sandpaper and gentle pressure, each step plays a vital role in refining the marble surface and creating a smooth and shiny surface.

1. Clean the surface:

Before mirror polishing, it is crucial to clean the marble surface thoroughly to avoid scratches and impurities from the polishing process. Use warm water and a mild detergent to gently wipe the surface to remove dust, dirt, and other contaminants. It is important to avoid leaving water stains on the surface and ensure the marble is clean and free of any debris that could affect the quality of the finish.

2. How to use sandpaper:

Soak the sandpaper in water for a while to soften it and make it suitable for polishing. When using sandpaper, you must switch to lower-grit sandpaper each time you polish. After each change of sandpaper, clean the surface with clean water to remove any residue and ensure a smooth transition between sanding stages.

3. Apply gentle pressure:

After applying a small amount of water, polish the marble surface in the direction of the surface grain. It is important to be gentle and avoid applying excessive pressure to prevent scratching the marble surface. By employing gentle techniques, one can refine the marble surface and obtain a smooth and shiny surface without compromising its integrity.

4. Polish with water:

During the polishing process, continually adding water to the sandpaper will help keep the surface moist. This helps the sandpaper move more smoothly across the surface and prevents excess heat from being generated, thus contributing to a more efficient and controlled polishing process.

5. Multiple polishing:

To achieve the desired effect, you must use sandpaper of different grits for multiple grinding and polishing operations. Using different grit grits of sandpaper will help refine the surface and achieve a smooth and shiny finish, ultimately enhancing the overall appearance of your marble surface.

6. Check the surface:

After polishing for a period of time, it is important to inspect the surface to evaluate the progress and determine whether the desired smooth shine has been achieved. If blemishes and stains remain on the surface, additional polishing with fine-grit sandpaper may be required. However, it is crucial to avoid over-polishing to prevent excessive wear on the surface and maintain its integrity.

Basic Precautions for Marble Mirror Polishing

1. Avoid heat: During the grinding process, it is crucial to avoid exposing the marble surface to high-temperature light. Excessive heat can affect the marble’s surface, possibly affecting the grinding process and the quality of the final finish.

2. Ensure air circulation: Maintaining proper air circulation during the grinding process is essential to prevent impurities such as sand and dust from adhering to the surface. Keeping the room well-ventilated helps maintain a clean and controlled environment for the grinding process.

3. Safety protection: Prioritizing safety protection during the grinding process is fundamental. It is necessary to wear personal protective equipment, including gloves, masks, and goggles, to protect against potential hazards associated with grinding, such as dust and airborne particles.

4. Maintenance after polishing: After completing the polishing process and achieving the desired effect, be sure to pay attention to post-polishing maintenance. Avoid placing heavy or sharp objects on the surface to prevent scratches and maintain the integrity of the polished surface.

Post time: May-24-2024