Learn Its Basic Composition and Functions

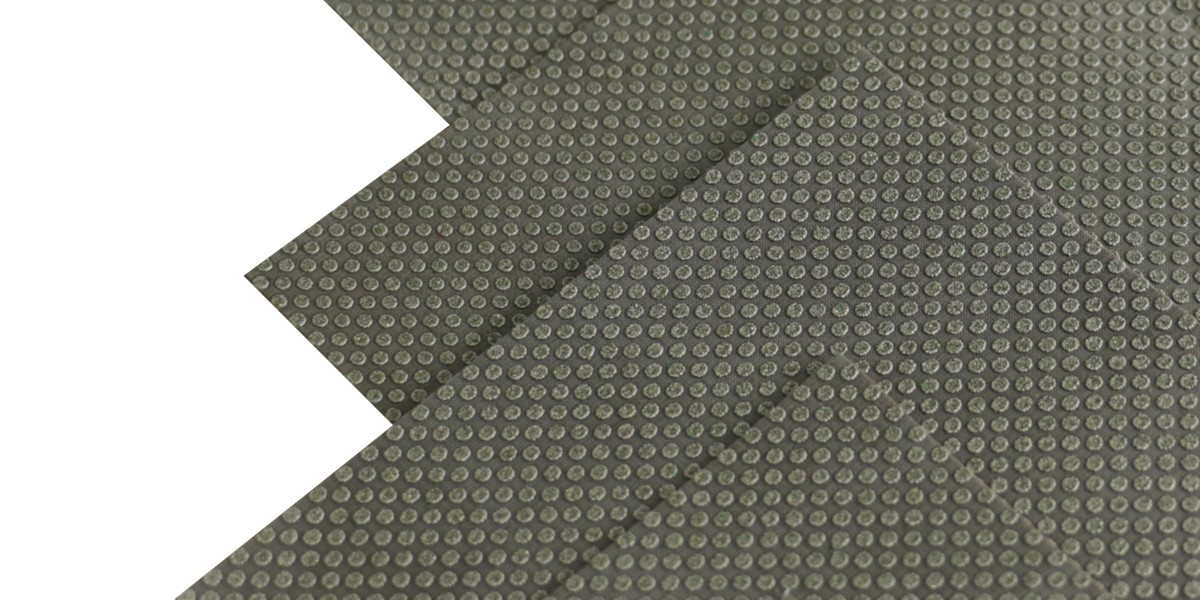

Carrier material: paper or base cloth

The carrier material of the sandpaper acts as a base to support the abrasive grains and provides the necessary structure for the sanding process. Sandpaper typically uses paper or a base cloth as the carrier material, each material has unique properties and is suitable for different applications. Paper-based sandpaper is commonly used for general sanding and finishing tasks, offering flexibility and ease of use. Cloth-based sandpaper, on the other hand, offers enhanced durability and strength, making it suitable for heavy-duty applications and demanding surfaces.

Abrasive grains: hard and tough materials

The abrasive grains of sandpaper are the key ingredient responsible for the actual grinding and polishing of the workpiece. These particles are typically composed of hard, tough materials such as quartz, glass, ceramics, and other abrasive minerals. The choice of abrasive grain depends on the specific requirements of the grinding and finishing task, including the hardness of the material being machined, the desired finish, and the desired level of accuracy. Different abrasive grains have varying levels of hardness, wear resistance, and cutting ability, allowing the sandpaper to be customized to suit specific applications and materials.

What is the material of sandpaper?

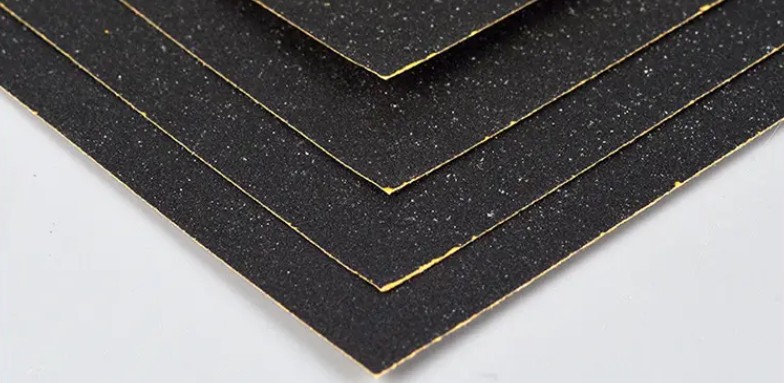

Diamond Sandpaper: Exceptional Hardness and Versatility

Diamond sandpaper is a general-purpose sandpaper with emery as abrasive grains. It is suitable for grinding almost all materials, including steel, wood, ceramics, tempered glass, marble, quartz stone, etc. The primary abrasive in diamond sandpaper is diamond, which is one of the hardest natural materials. It has very high hardness, excellent wear resistance, and high-temperature resistance. Diamond sandpaper is known for its excellent performance in high-temperature, high-pressure, and humid environments. Diamond sandpaper has an extremely small grit size that produces a high-finish surface, making it ideal for precise and uniform results in a variety of applications.

Silicon carbide sandpaper: high strength and versatility

Silicon carbide sandpaper is a common type of sandpaper that utilizes silicon carbide as the abrasive particles. Suitable for grinding metal, stone, and non-metallic materials. Silicon carbide sandpaper has the characteristics of high strength, high hardness, excellent wear resistance, high-temperature resistance, and corrosion resistance. These properties make it suitable for a wide range of applications, including metalworking, woodworking, and surface finishing where high-performance abrasives are required.

Aluminum Oxide Sandpaper: High Speed and Efficiency

Aluminum oxide sandpaper is another common type of sandpaper that uses aluminum oxide as the abrasive particles. Suitable for sanding wood, paint, plastic, and other materials. Alumina sandpaper is known for its high speed, efficiency, and strong cutting power. It is widely used in woodworking, automotive refinishing, and general surface preparation due to its ability to provide consistent and reliable results.

In summary, sandpaper is an indispensable tool in a variety of industries and applications, offering a variety of abrasive materials to meet specific grinding and finishing needs. Each type of sandpaper has unique properties that make it suitable for specific materials and applications. By understanding the composition and properties of different types of sandpaper, the most appropriate abrasive material can be selected to obtain the best results in a variety of grinding and finishing operations.

Diamond Sandpaper vs. Regular Sandpaper: Know the Key Differences

Different materials

One of the main differences between diamond sandpaper and regular sandpaper is its abrasive material. Diamond sandpaper is made from synthetic diamond particles as the abrasive, taking advantage of the diamond’s exceptional hardness and wear resistance. In contrast, regular sandpaper typically uses materials such as aluminum oxide or silicon carbide as the abrasive. Diamond sandpaper uses diamond as the abrasive material, giving it superior cutting ability and service life, and is suitable for grinding and polishing hard materials.

Different service life

Due to diamond’s advantages as an abrasive material, diamond sandpaper typically has a longer service life than regular sandpaper. The excellent hardness and wear resistance of diamond makes the service life of diamond sandpaper several times or even dozens of times longer than ordinary sandpaper. This extended service life is one of the key reasons why craftsmen often prefer diamond sandpaper for demanding applications that require durability and consistent performance.

Different scope of application

The applicable range of diamond sandpaper and ordinary sandpaper differs according to the materials being processed. Diamond sandpaper is specifically used to grind and polish hard materials such as marble, ceramics, and cement. Its exceptional hardness and cutting ability make it ideal for challenging surfaces that require precision and durability. Regular sandpaper, on the other hand, is suitable for sanding materials such as wood and plastic. When using any type of sandpaper, it is important to select the appropriate grit size based on the hardness of the material to achieve the desired sanding and polishing results.

Post time: Apr-05-2024