Safety and Environmental Protection

To ensure safety and protect the environment during sanding, follow these guidelines:

Wear a mask: Always wear a mask to protect yourself from inhaling dust particles.

Use protective gear: Dust can be harmful to the skin when working with materials such as copper, lead, carbon fiber, and fiberglass. Wear rubber gloves and protective clothing to prevent any skin damage.

Minimize dust contamination: Dust particles can easily get into the air during sanding. Consider using a wet sanding method, such as water milling, to reduce dust. However, be aware that using a water mill may pollute the water. Use separate buckets for each grid to prevent cross-contamination. Proper Disposal: Dispose of sanding waste and dust properly in accordance with local regulations. Avoid allowing dust to enter water sources or the environment.

Ventilation: Make sure the sanding area is well-ventilated to reduce the concentration of dust in the air. Remember that safety precautions and environmental protection should always be prioritized when sanding.

Choosing the Right Sandpaper Mesh for Different Materials

Achieving high mesh counts can be difficult for fibrous materials such as wood and leather. It is recommended to start with around 200 mesh and work your way up to 800 or 1000 mesh for a smooth finish. For higher meshes on wood and leather, the original material should be solid and have an oily wax coating. With a smooth hard surface like glass, hardwood or brass, dip it in a chemical filler to bind the fibers and further enhance the finish.

For metallic materials, it is recommended to start with a grid of around 80 and gradually double the grid size. Good results are usually obtained with 1500 or 2000-grit sandpaper. For higher purpose metal polishing, consider 3000 or 5000 grit sandpaper. However, it is important to note that the effect of higher grit sandpaper is minimal. In this case, it is recommended to use a polishing paste and a clean cloth, paper or wool wheel for better results. Alternatively, a chemical polish can be used to achieve a mirror-like finish. However, it is important to proceed with caution as such chemicals may not be suitable for personal health.

Plastic, carbon fiber, fiberglass and stone items tend to have a matte finish on their original surface. Sandpaper options for these materials are relatively limited, typically ranging from 800 to 2000 grit. In order to obtain a higher mesh, it is recommended to use a polishing paste. When dealing with scratches on these materials, it is critical to ensure that the surface can be uniformly thinned to match the scratch depression. If this is not possible, it is recommended to avoid spot sanding as this may result in uneven surfaces. In this case, applying polishing paste to the entire surface and using a wool wheel can help reduce visible marks. Choosing the right sandpaper web for different materials is critical to achieving the desired level of polish.

Use of Sandpaper

When starting a sanding project, it is recommended to start with low-grit sandpaper. This ensures that the sandpaper does not clog easily, allowing for effective material removal. During this initial stage, dry grinding is best done without water. Accumulated powder must be cleaned up immediately after each pass. This ensures a clean work surface and allows an accurate assessment of the evenness and straightness of the sandpaper marks. If the desired effect is achieved, you can move on to the next mesh. At this stage it is crucial to change the direction of the grind, forming a wider angle to the previous mark to avoid uneven surfaces. As the mesh number increases, it is necessary to switch to wet grinding, using water as a lubricant. It is important to note that after each wet sanding, the sandpaper and workpiece surface must be thoroughly cleaned to remove any low-mesh particles that may contaminate the surface. If the grit does stain the surface, it is recommended to replace the sandpaper with a higher-grit alternative. In addition, it is recommended to store a separate bucket of water for each mesh to minimize environmental pollution. At the end of each day, buckets and any debris should be disposed of or stored properly to maintain a clean work environment.

When sanding with extremely high grit, such as 2000 or 5000 grit, monitoring the condition of the sandpaper becomes critical. Clogged sandpaper can render further sanding ineffective and may even cause localized overheating and bonding. If the sandpaper becomes clogged, it must be carefully washed with water or oil to remove any clogging. It’s important to remember that using clogged sandpaper may result in poorer results. Mastering the art of sanding requires an in-depth knowledge of the different techniques depending on the grit of the sandpaper. Starting with a low grit for efficient material removal, progressing to higher grits for a finer finish, and incorporating wet sanding when necessary is a key components of a successful sanding process. By following these techniques and keeping the sandpaper and workpiece clean, achieving the desired surface quality becomes an achievable goal for all sanding enthusiasts. Remember that sanding is an investment in the quality of the final product. By investing the proper time and attention in your sanding method, you can unlock the true potential of your woodworking and finishing projects.

Making and using sanding blocks

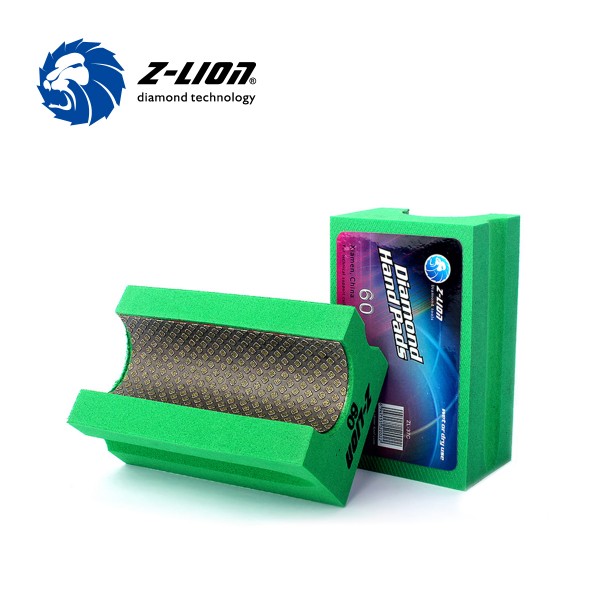

The sanding block is designed to match the surface of the workpiece, ensuring an even sanding experience. For large flat surfaces, it is critical to use a sanding block with a flat surface that can be securely clamped or attached with sandpaper. However, when working on curved or irregular surfaces, the sanding block should be made of a bendable material such as bamboo or sponge. This allows for seamless sanding along radii and contours, giving consistent results. Industrial products that meet these specific needs are readily available. The most common of these are nail polish abrasives, which are great for giving your nails a polished finish. Additionally, emery blocks are an excellent alternative to traditional sandpaper, offering high cutting power and durability. These industrial-grade tools are designed to withstand rigorous use and deliver exceptional results.

In some cases, it is necessary to use profiled sanding sponges, such as those used for leather edge trimming and sanding. These blocks usually have U-shaped grooves to fit the contours of the workpiece. When making such sand blocks, the convenience of changing the sandpaper must be considered.

Sanding block chamfering is another critical aspect that should not be overlooked. Even during use, the edges of the sandpaper have the potential to flake off. To prevent the sandpaper from overlapping and potentially damaging the workpiece, any flaking areas should be repaired immediately. By addressing these issues in a timely manner, the integrity of the sandpaper is maintained, ensuring a consistently smooth and flawless finish.

Post time: Aug-25-2023