In the stone processing industry, edge grinding, diagonal, and chamfering of stone slabs are essential processes, which have a great impact on the appearance, durability, and practicality of the stone. These treatments play a vital role in refining the edges of the stone slab, enhancing its aesthetic appeal, and ensuring it is suitable for a variety of applications. This article will discuss the definition, process steps, application scenarios, and importance of stone slab edge grinding, diagonal, and chamfering in stone processing.

Stone Edge Grinding Process

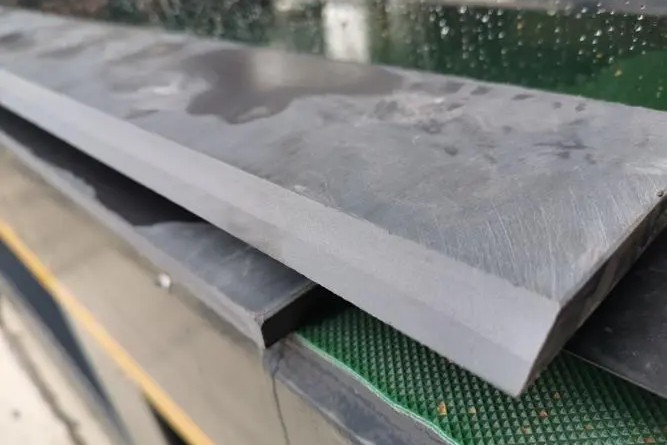

Stone plate edge grinding is a key process in stone processing, aiming to refine the edge of the stone plate to achieve a smooth, flat, and beautiful surface effect.

The meaning of stone slab edge grinding:

In the stone processing industry, stone slab edge grinding is a key process, which directly affects the overall quality, durability, and aesthetics of the stone. By refining the edges of stone slabs, edging enhances the appearance, safety, and practicality of the stone, making it suitable for a wide range of applications in architecture, interior design, and decorative installations.

Process steps:

The process of slate edge grinding typically involves several key steps. First, determine the shape and size of the edge based on the design requirements and the actual characteristics of the stone. Then, use a professional stone edger or hand tools to polish the edges of the stone to ensure a smooth and even edge. Throughout the grinding process, the flatness and smoothness of the stone edges must be constantly checked to ensure that they meet the design requirements. Finally, the polished stone edges are cleaned and maintained for subsequent use.

Application scenarios:

The application scenarios of stone plate edge grinding are diverse and extensive, covering various fields such as home decoration, public buildings, and landscaping. In home decor, slate edging is often used to enhance the appearance of floors, walls, countertops, and other architectural elements. In public buildings, it is used for the decoration of stairs, corridors, halls, and other structural components. Additionally, in landscaping, stone edging is used to pave pathways, squares, flower beds, and other outdoor areas, contributing to the overall beauty and functionality of the landscape.

The importance of edge grinding of stone slabs:

The importance of stone slab edging is that it enhances the overall quality, durability, and usefulness of the stone. By refining the edges of stone slabs, edge grinding helps create a smooth, flat, and visually appealing surface, ensuring the stone is suitable for a variety of applications in both residential and commercial settings.

Z-LION WMC66S diamond flap discs feature semi-rigid diamond louvers that provide high cutting rates, allowing users to quickly and efficiently grind rough edges and imperfections on all types of stone. Whether working with granite, marble, or other natural or engineered stone, these grinding wheels are engineered to provide superior performance and durability.

Stone Diagonal Process

In the field of stone processing, the diagonal processing of stone slabs plays a vital role in ensuring the seamless integration and beauty of the stone installation. This technique involves adjusting the angles of the stone slabs to meet design specifications for optimal splicing and installation with other stone slabs. The careful execution of the diagonal process helps maintain the quality and visual harmony of the stone application, making it an integral aspect of stone fabrication and installation.

The process of machining diagonal slate involves several basic steps, each of which contributes to the precision and accuracy of the final result. First, determine the adjustment angle according to the design requirements and the specific characteristics of the stone slab. Specialized stone-cutting machinery or hand tools are then used to cut or polish the slabs so that their angles align with specified design parameters. Throughout the entire process, we carefully inspect the flatness and angular accuracy of the stone slabs to ensure they perfectly meet design specifications. Finally, the adjusted slate is meticulously cleaned and maintained, ready for seamless integration into the intended application.

The versatility of the diagonal slate craft is reflected in its wide range of applications in a variety of architectural and decorative settings. In building curtain wall construction, diagonal craftsmanship is often used to facilitate the seamless splicing and installation of stone slabs, contributing to the structural integrity and visual appeal of the building. Likewise, in the field of stone floor and wall decoration, diagonal workmanship plays a key role in adjusting the angle of the stone slabs to ensure a harmonious and precise fit with the surrounding floor or wall. The stone beveling process is about more than technical adjustments; it embodies the fusion of precision and aesthetics, enhancing the visual impact and functional integrity of the stone installation. By carefully arranging the stone slabs to meet design requirements, this process not only enhances the structural cohesion of the architectural elements but also helps enhance the overall visual appeal of the stone application.

Stone Corner Cutting Process

Stone cutting is a basic process in the field of stone processing and plays a key role in cutting stone slabs into specific shapes and sizes to meet design requirements and actual needs. This complex process is critical to achieving the required shape and dimensional accuracy of the stone slabs, making it the cornerstone of precision and craftsmanship in the field of stone manufacturing and installation.

The stone-cutting process involves several key steps, each of which contributes to the precision and accuracy of the final product. Initially, the shape and size to be cut are determined based on design specifications and the unique characteristics of the stone slab. The slabs are then carefully cut using specialized stone cutting machinery or hand tools such as grinder flap discs, ensuring that the resulting shape and dimensions comply with the specified design parameters. Throughout the cutting process, we pay great attention to verifying the shape and dimensional accuracy of the stone slabs to ensure they perfectly meet the design specifications. Finally, the cut stone slabs are meticulously cleaned and maintained, ready for seamless integration into the intended application.

The application scenarios of stone slab cutting are diverse and far-reaching, covering various fields such as architecture, art, and landscape. In the field of building components, slate-cutting technology is often used to make columns, beams, carvings, and other structural elements, helping to ensure the structural integrity and aesthetics of the building. Similarly, in the field of stone carving, stone slab-cutting technology can also create sculptures of various shapes and postures, reflecting the fusion of artistry and precision. In addition, in the garden landscape, stone slab cutting is used to shape landscape facilities such as flower beds, seats, and landscape walls, adding a touch of elegance and sophistication to the outdoor space.

Stone plate cutting, edge grinding, and diagonal processing together constitute the three indispensable process links in stone processing. These processes are not only crucial to the appearance and durability of the stone but also directly affect its practicality. Therefore, strict attention to quality control and continuous technical improvement in these processes is crucial to ensure that the quality and beauty of the stone slabs are always maintained to the highest standards.

Post time: May-31-2024