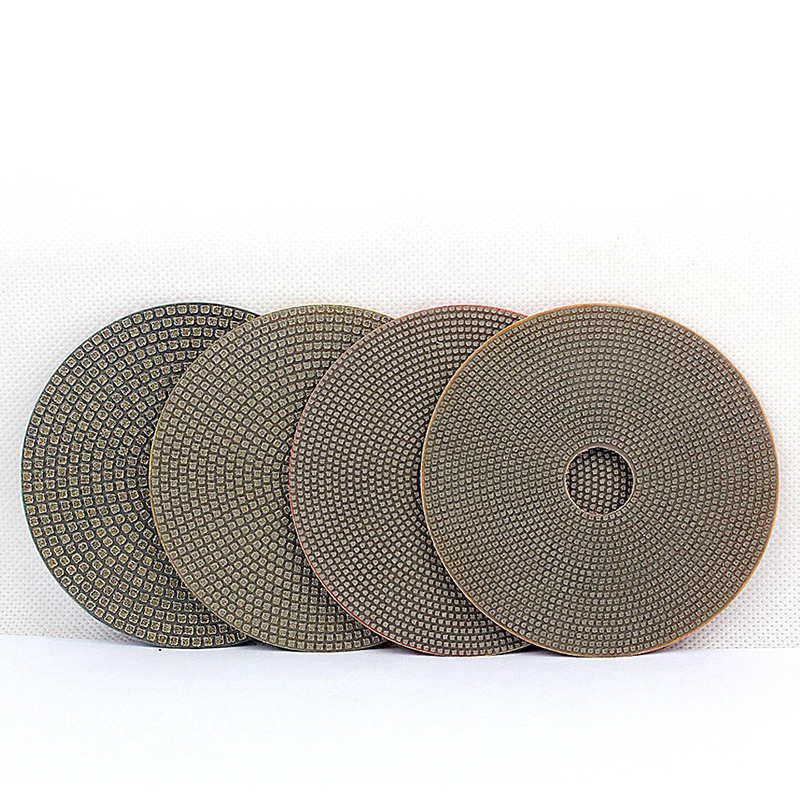

Diamond polishing pads have many advantages

1. Power saving:

The diamond polishing sheet is used to grind stone due to its sharpness. Since the pressure of the grinding head can be greatly reduced, the mechanical wear is reduced. At the same time, the processing of the same thickness of the plate can reduce the stone damage rate, and can also process the thinner stone.

2. Production efficiency:

Due to its sharpness and wear resistance, the diamond polishing sheet can stably increase the transmission speed of the conveyor belt, thereby improving production efficiency.

3. High luminosity:

The diamond polishing sheet can improve the luminosity of the stone by more than 10 degrees. Due to the production process of diamond polishing pads, the quality of the abrasive pads can be avoided due to the reduction of magnesium oxide activity and the change of maintenance conditions in the production process of rhombohedral abrasive pads; due to the production and testing process and transportation process of diamond are stricter than those of silicon carbide. , The particle size uniformity of diamond is much greater than that of silicon carbide, so the possibility of stone scratches and photometric instability is greatly reduced.

4. Reliable quality:

Due to the current large-scale production of diamond, its price has dropped significantly, so the price of diamond polishing pads has also dropped significantly. In addition, computer-controlled production equipment and technology can be used in the production of diamond polishing pads, while diamond polishing pads The production of blocks still adopts simple artificial production equipment and technology, and the production cycle is more than one month, which affects the quality for a long time, and the quality cannot be stable.

It is precisely because of the many advantages of diamond polishing pads that it is widely used.

Application of diamond polishing pads:

1. It is used for the processing of artificial stone, granite and marble, etc. It has a complete and standardized particle size color system and good flexibility. It is handy in processing lines, chamfers, curved plates and special-shaped stones, and there are various shapes and specifications to choose from. , Various particle size numbers are easy to identify, and can be used flexibly with various hand mills according to needs and habits.

2. It is used for the treatment and renovation of various floors and steps after granite, marble and artificial stone slabs are laid. It can be used flexibly with various hand grinders or renovation machines according to needs and habits.

3. It is used for the renovation of industrial floors, warehouses, parking lots and other concrete floors or various aggregate hardener floors, especially for today’s popular liquid hardener floor projects. It can be flexibly matched with various hand grinders according to needs and habits. Machines or refurbished machines are used, and grinding discs of different particle sizes are selected for rough grinding, fine grinding and polishing.

Post time: Jun-23-2022