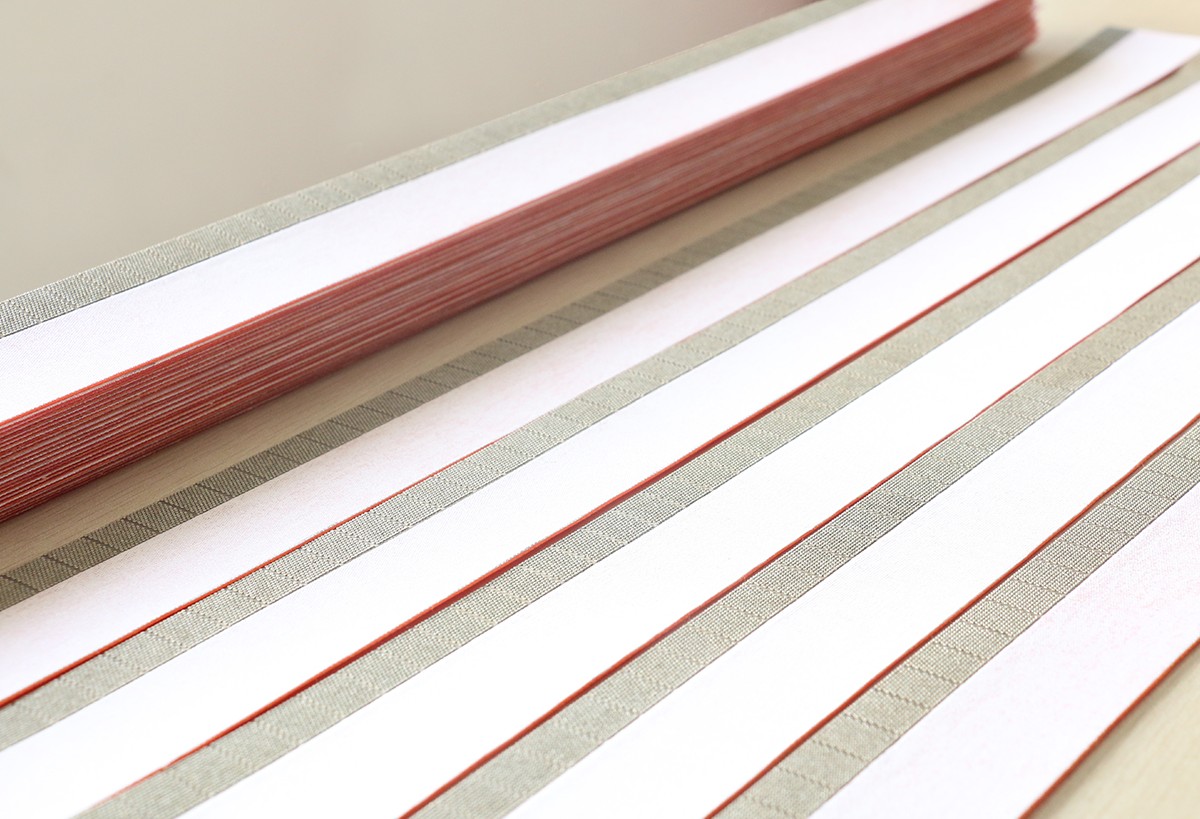

Z-LION Diamond strips for abrasive strip brush system designed for sanding wind mill turbine blades

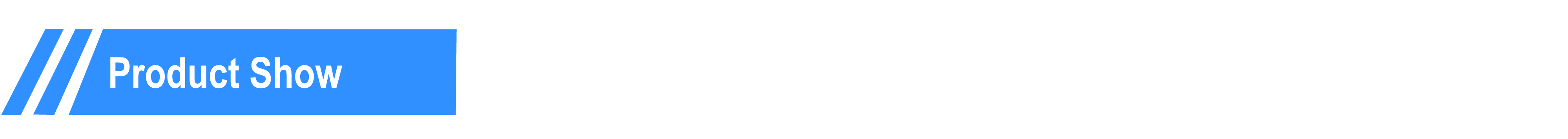

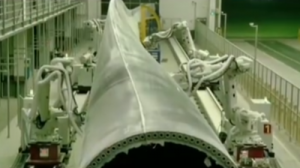

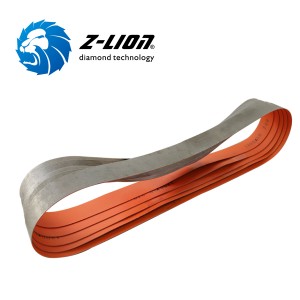

Z-LION Diamond strips are widely used in wind energy industry. Working as an important part of the abrasive strip brush system in a robotic sander for sanding and cleaning the expansive surfaces of wind turbine blades simultaneously to eliminate defects and achieve a uniform finish to ensure optimal performance.

Features of Z-LION Diamond strips for abrasive strip brush system designed for sanding wind mill turbine blades are as follows:

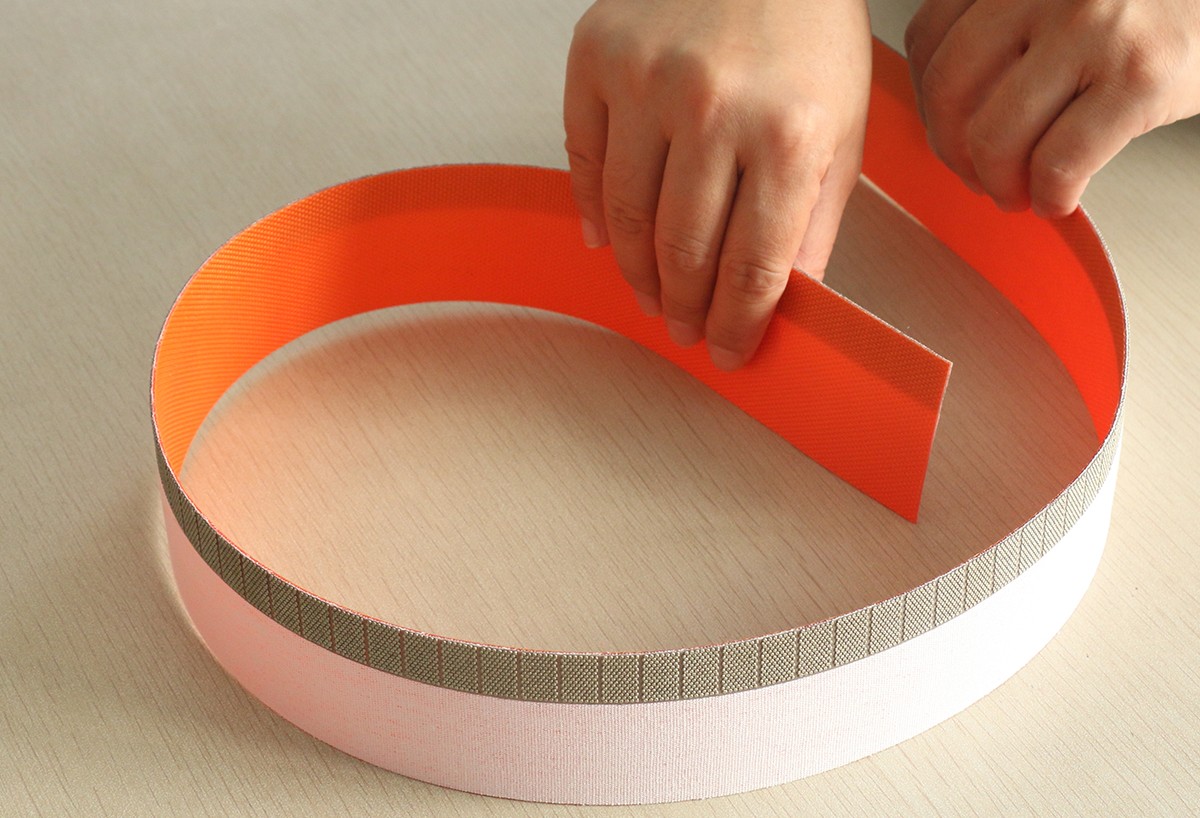

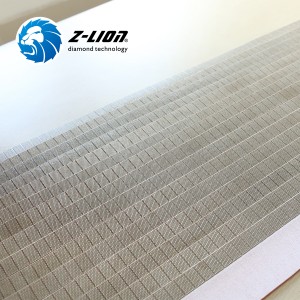

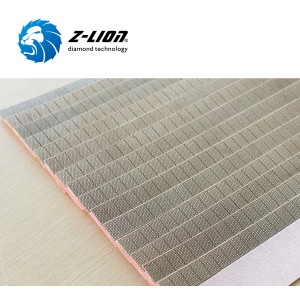

• The specially designed diamond coated surface prevents the sanding strip from clogging, and minimizes thermal loading on sensitive composite resins, performs flexible, fast, and safe sanding of wind turbine blades.

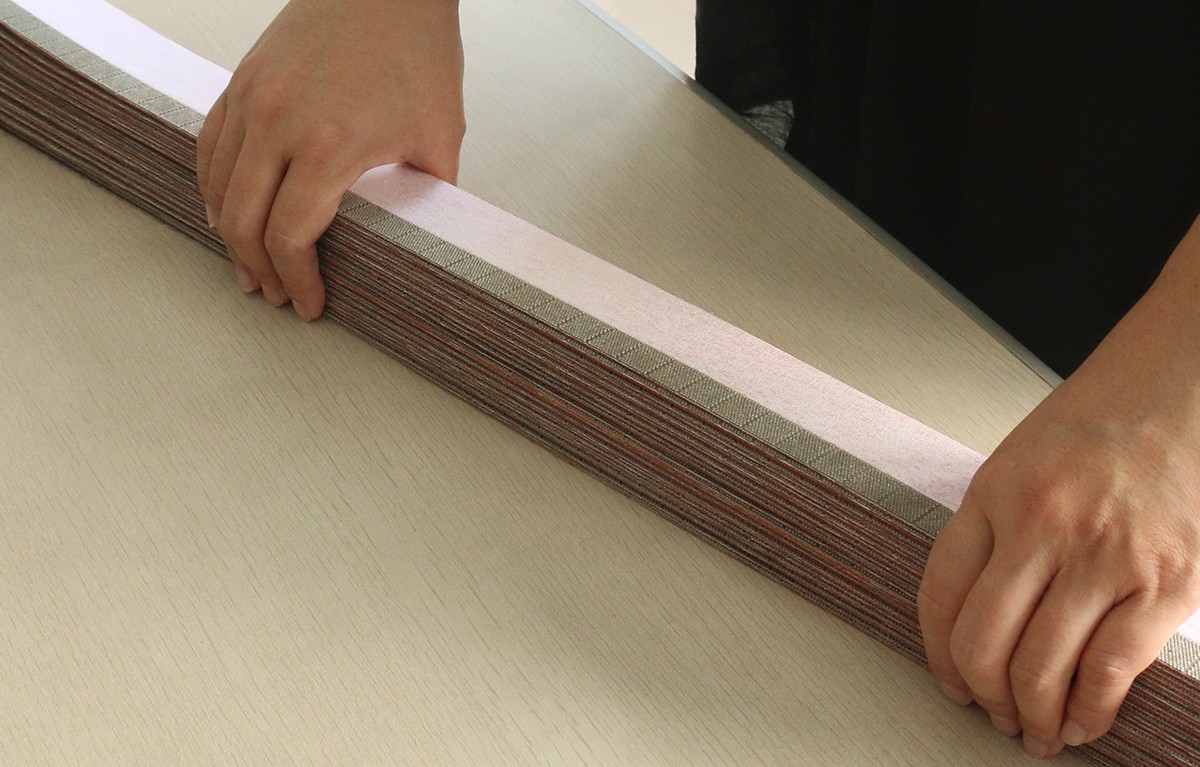

• Diamond impregnated abrasive strips ensures faster sanding and greater efficiency, large surfaces can be finished with minimal exertion.

• Diamond coated strips offer superior durability compared to conventional abrasives like ceramic, zirconium, aluminum oxide, silicon carbide, perfect for robots and automated blade sanding.

• Diamond strips involved in the system for sanding and cleaning simultaneously.

• Diamond strips involved in the system to ensure fine sanding and meticulous finishing for improved blade performance.

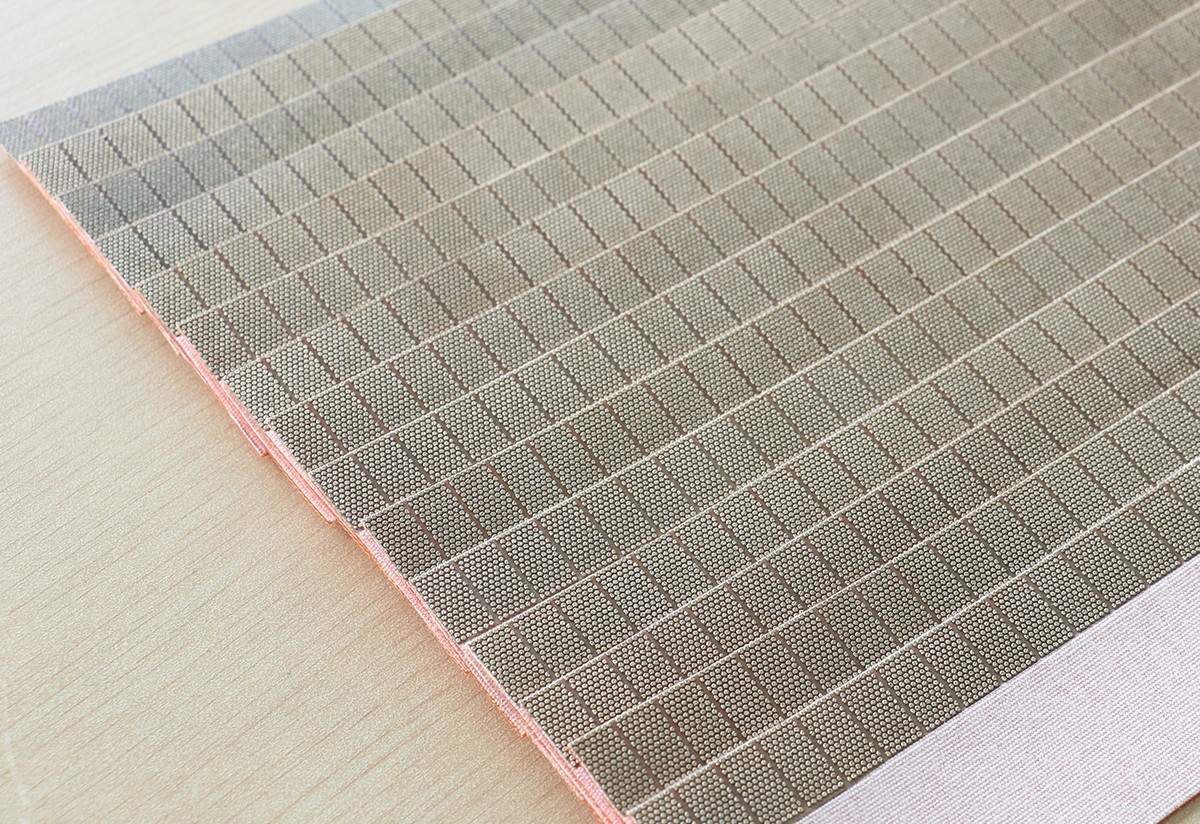

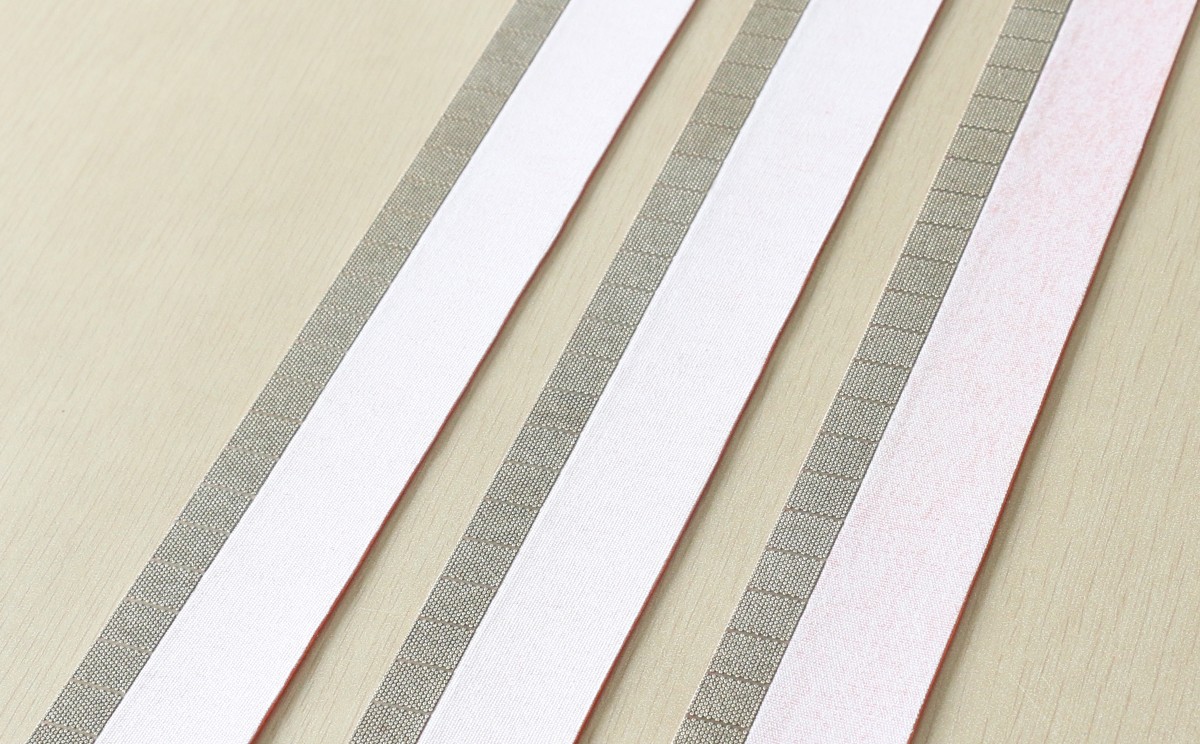

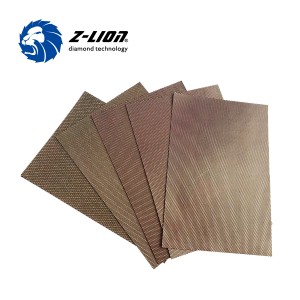

Available sizes 1000x15/45mm, 1000x15/40mm, 800x15/50mm, 800x15/45mm, 800x15/40, 260x10/40mm, etc.

Available grits 60# 120# 200# 400# (other grits are available upon request)

Surface pattern can be custom made.

Trim height and width can be custom made, no cut is also available.

| Product Name: | Diamond strips |

| Item No.: | ZL-123EB |

| Brand: | Z-LION |

| Working surface: | Electroplated flexible diamond sheet |

| Features of the product: | • The specially designed diamond coated surface prevents the sanding strip from clogging, and minimizes thermal loading on sensitive composite resins, performs flexible, fast, and safe sanding of wind turbine blades. • Diamond impregnated abrasive strips ensures faster sanding and greater efficiency, large surfaces can be finished with minimal exertion. • Diamond coated strips offer superior durability compared to conventional abrasives like ceramic, zirconium, aluminum oxide, silicon carbide, perfect for robots and automated blade sanding. • Diamond strips involved in the system for sanding and cleaning simultaneously. • Diamond strips involved in the system to ensure fine sanding and meticulous finishing for improved blade performance. |

| Popular sizes: | 1000x15/45mm, 1000x15/40mm, 800x15/50mm, 800x15/45mm, 800x15/40, 260x10/40mm, etc. |

| Available sizes: | Can be custom made |

| Popular grits: | 60# 120# 200# 400# |

| Available grits: | 30# 60# 120# 200# 400# 600# 800# 1000# 2000# 3000# |

| Usage: | Wet and dry |

| Applied machine: | Semi automatic sanders, automatic sanders, robotic sanders, etc. |

| Applications: | Used in the wind energy industry for sanding wind mill turbine blades, molds, nacelles, etc. |