diamond abrasive belt grinding is the process of processing the workpiece by using diamond abrasive belts as abrasive tool, supplemented by contact wheel (or grinding plate), tensioning wheel, driving wheel and other grinding head main parts, as well as tensioning quick-change mechanism, deflection adjustment mechanism, anti-dust (suction) device and other functional parts. Specifically, the diamond abrasive belt is sleeved on the outer surface of the driving wheel and tensioning wheel, and the diamond abrasive belt is tensioned and operated at high speed. The workpiece is ground or polished with corresponding contact and appropriate grinding parameters according to the workpiece shape and processing requirements,.

diamond abrasive belt grinding features:

① diamond abrasive belt grinding is a kind of elastic grinding, so diamond sanding belt grinding is a complex processing process with multiple functions of grinding, grinding and polishing.

② Abrasive grains on diamond abrasive belt have stronger cutting ability than abrasive grains of grinding wheel, so the efficiency of diamond abrasive belt grinding is very high.

③ The grinding speed is stable. Because the contact wheel is not very worn, the diamond abrasive belt can move and maintain a constant speed, instead of grinding the smaller the diameter, the slower the speed.

④ High grinding accuracy of diamond abrasive belt. Due to the improvement of the manufacturing quality of diamond abrasive belt and the production level of diamond abrasive belt grinder, diamond abrasive belt grinding has already entered the ranks of precision and ultra-precision machining.

⑤ The cost of diamond abrasive belt grinding is low. This is mainly reflected in:

(1) Compared with grinding wheel grinder, diamond abrasive belt grinder has simple structure and short transmission chain. This is mainly due to the light weight of diamond abrasive belt, small grinding force and small vibration in the grinding process. The requirements for the rigidity and strength of the machine tool are far lower than that of the grinding wheel.

(2) diamond abrasive belt grinding is easy to operate with less auxiliary time. Whether it is manual or motorized diamond sanding belts grinding, its operation is very simple. From replacing and adjusting the diamond abrasive belt to clamping the workpiece to be processed, all these can be completed in a very short time.

(3) The diamond abrasive belt grinding ratio is large, the machine power utilization rate is high, and the cutting efficiency is high. This reduces the cost of tools and energy for cutting materials of the same weight or volume, and the occupation time is short.

⑥ Belt grinding is safe and reliable, with low noise and dust, easy to control and good environmental benefits. Because the sand belt itself is light, there is no danger of injury even if it is broken. The diamond abrasive belt grinding is not as serious as the grinding wheel. Especially in dry grinding, the abrasive debris is mainly the material of the workpiece to be processed, and it is easy to recover and control the dust. Because the rubber contact wheel is used, the diamond abrasive belt grinding will not form a rigid impact on the workpiece like the grinding wheel, so the processing noise is very small.

⑦ The diamond abrasive belt grinding process is flexible and adaptable. This is reflected in:

(1) diamond abrasive belt grinding can be very convenient for grinding plane, inner, outer circle and complex curved surface. A belt grinding head device is designed as a functional part, which can be installed on the lathe for rear grinding, and can also be installed on the planer for use. At the same time, it can also be designed as a variety of special grinding machines. Using this feature of diamond abrasive belt grinding can easily solve the precision machining of some difficult parts, such as ultra-long, ultra-large shafts and plane parts.

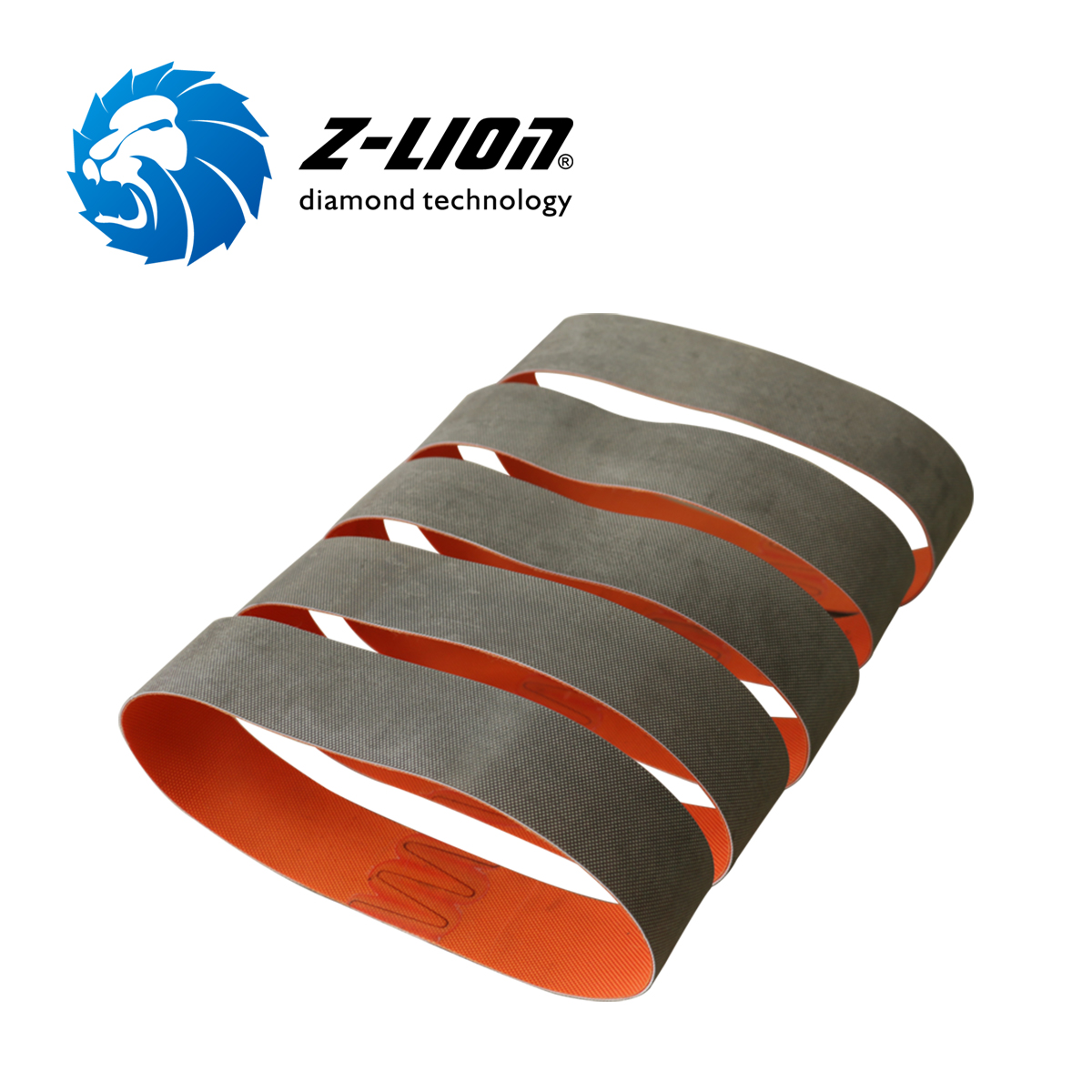

(2) The base material, abrasive and binder of diamond abrasive belt have a wide selection range, which can meet the needs of various applications. The size, length and width of the diamond abrasive belt also have various specifications, and there are many forms to choose from, such as roll and ring. For the same workpiece, diamond abrasive belt grinding can adopt various grinding methods and technological structures for processing.

Post time: Feb-24-2023