-

For diamond grinding discs, the choice between dry and wet grinding is crucial, directly impacting machining results in various applications. Each method has its own advantages and disadvantages, significantly affecting the grinding process, surface quality, and overall efficiency. This article w...Read more »

-

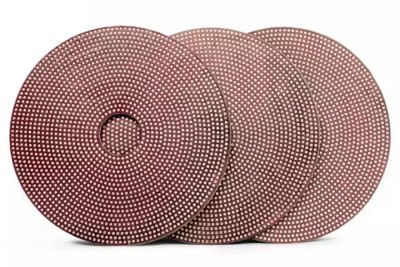

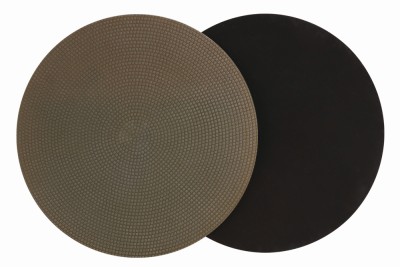

What Are Diamond Grinding Discs? Structure of a diamond grinding disc Diamond grinding discs are composed of three main materials, each of which plays a specific role: Basal layer: The base layer is typically made of a robust material such as steel or aluminum alloy. This layer provides the nec...Read more »

-

Diamond grinding pads, also known as diamond polishing pads, are a crucial component of bonded abrasive grinding technology. These pads are made by chelating diamond micropowder with resin, resulting in high hardness, excellent wear resistance, and superior efficiency. Their unique properties mak...Read more »

-

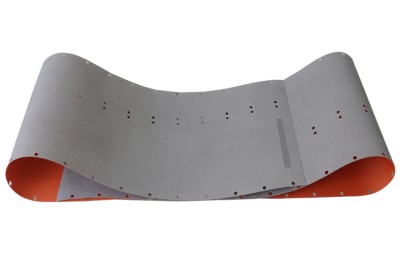

The textile manufacturing industry is a complex ecosystem that heavily relies on high-precision machinery to ensure consistent product quality and maximize production efficiency. In this environment, effective maintenance is crucial to prevent downtime and maintain the integrity of the production...Read more »

-

Diamond flap discs represent a major innovation in the field of abrasive tools, designed for the efficient and precise machining of hard materials. Unlike traditional abrasive wheels made of abrasives such as silicon carbide or zirconium oxide, diamond flap discs utilize the unparalleled hardness...Read more »

-

In the fiercely competitive high-end textile market, consumers are no longer solely focused on product accessibility and price. Today, they seek textiles that offer superior quality, comprehensive functionality, and an unparalleled wearing experience. The entire process from fiber to yarn is intr...Read more »

-

When working with glass, sharp edges can sometimes be created, easily causing cuts and injuries. Whether you’re dealing with broken glass, glass for a DIY project, or freshly cut glass, for safety reasons, you must sand down the sharp edges. Smooth with Sandpaper 1. Prepare materials: You’ll n...Read more »

-

Polishing the edges of quartz stone is a delicate process that enhances the overall look and durability of the stone. Whether you’re working on countertops, tiles, or other quartz surfaces, the right tools are essential for achieving a smooth, glossy finish. This article outlines the tools neede...Read more »

-

Granite is one of the hardest natural stones, making it an ideal choice for countertops, floors, and other surface materials due to its durability and beauty. However, in some cases, granite surfaces may require polishing, such as removing imperfections, preparing for installation, or achieving a...Read more »

-

Ceramic products are highly sought after for their unique texture, durability, and aesthetic appeal. However, over time, ceramic surfaces may develop scratches, dullness, or stains, affecting their appearance and overall look. To address these issues, ceramic polishing pads have emerged as essent...Read more »

-

Tile Polishing Method There are several ways to polish ceramic tiles, each with its own advantages and disadvantages: 1. Hand polishing: Description: This method involves manually sanding the tile surface using sandpaper or abrasive discs. Benefits: Manual polishing allows for precise control of...Read more »

-

1. Choose the Right Sanding Belt The choice of abrasive belt is crucial to reducing sparks during grinding. Here are some considerations: Grit size: Choose a fine or extra-fine belt. These belts have less friction and generate less frictional heat than coarse belts, thus preventing sparks. Fine b...Read more »